Quality Control

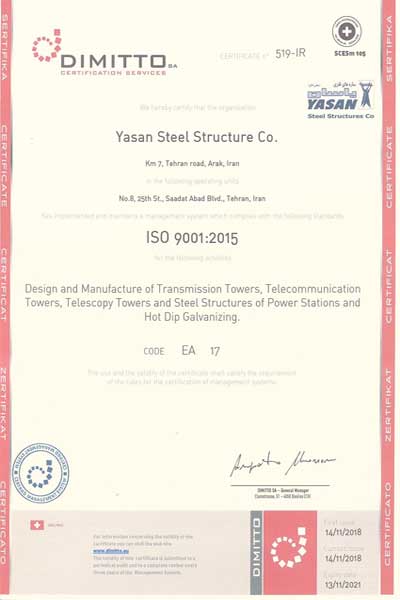

Yasan manufacturing unit are qualified by world class ISO 9001, 18001, 14001 standards (bottom). Productions system are controlled by EN 1090 and Galvanizing system apply ASTM A123 standard and Welding system is conformed to applicable standard (ISO, DIN, CEN, and …) as per employer request.

Quality control of raw materials

The raw materials used in all kinds of metal structures are checked according to international standards. All purchased materials, including corners, zinc ingots, iron sheets, pipes, bolts and nuts, wires, fittings and other items needed in the production and implementation of the tower are evaluated by the quality control team with calibrated instruments and any defects Or the discrepancy is reported directly to the CEO.

Production quality control

The production of telescopic and mesh towers is considered a heavy industrial process, but it is very accurate and sensitive with fluctuations of up to hundredths of a millimeter. All drillings, cuts and weldings must be defined according to the plan according to the standard. In case of any discrepancy, the part will be corrected, otherwise the part will be scrapped and re-produced.

Laboratory

Also, in order to ensure sufficient accuracy, measuring instruments are calibrated under special laboratory conditions and using approved reference blocks and based on the standards and supervision of the standard institute during certain periods of time. Therefore, every time the parts are tested, a valid certificate is presented as shown in the pictures below. All the tests required in the process of purchasing raw materials and producing parts are chemically, physically and mechanically to ensure the quality of the products produced in the laboratory. This unit operates under the supervision of the quality control unit. The use of accurate measuring tools under controlled laboratory conditions has made this unit a reliable reference for measuring different stages of production with related standards.

Welding quality control

All the welders of Yasan company have a valid welding certificate, which is done periodically to test and renew the certificate. This not only improves the quality of welding, but also prevents the wastage of raw materials due to welding errors. Among the tests that can be performed in the company, we can mention VT, PT, MT tests.

Galvanized quality control

Galvanization of metal parts is done according to ASTM A 123 standard. According to this standard, things like coating thickness, adhesion, error rate in the process, etc. are mentioned. Quality control experts conduct random tests of parts based on the patterns of this standard, and if defects are found, they are corrected, otherwise they refer the parts to the relevant warehouse for stripping the zinc coating and re-galvanizing.

Methods

The First Step is raw materials check which must pass following steps to be accepted :

Material Dimensions

Chemical Analysis

Appearance Quality

Mechanical Test

Production Control

During process of fabrication, hole diameter and other dimensional parameters are checked and recorded in a table sheet for weekly reports.

In semi-finished depot, products are randomly checked and recorded.

Specialized quality controllers check parts quality before galvanizing while all parts are washed with water and acid.

Galvanizing process is control by checking chemical analysis, optimum temperature of Zinc furnace.

Laboratory

Laboratory plays critical role in quality products. All input, production procedures and output are checked in Lab. This unit is located in QC department to ensure about quality. The lab enables Yasan Co. to Control physical, chemical and mechanical attribute of raw materials, production process and final products. This control is happen by accurate equipment and tools which are periodically checked and calibrated by accredited organizations.

Quality Strategy

Definition of quality strategy in Yasan Company is categorized by ISO standards which is our competent indication to provide quality product for transmission line projects. The outlines are list as bellows:

To Fabricate, install and deliver quality products according to international specification on agreed time.

To create proper opportunities for employees to be trained in order to promote engagement level to reach company’s targets.

To attempt for incrementing customers satisfaction.

To continuously improve procedures of business and applied technics

To establish mutual profitable connections with suppliers’ chain.

Final Product

Final products are checked for thickness and stickiness of covered Zinc on parts. After packing process, order is controlled by Final Product Quality Inspectors who control bundling, weight of each bundle, right storing and finally right loading on board.

After all, client has this right to test any part of bundle in terms of mechanical and chemical component before shipment. This test is typically implemented in presence of client, consultant and Yasan’s agents.