Technical services

Our technical services divide to three main sections.

First, Pre-Production Services. Second, Production Services.

Finally, Post-Production.

Engineering Services

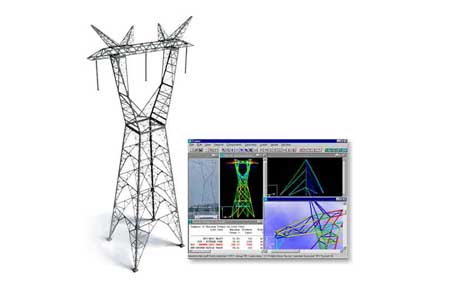

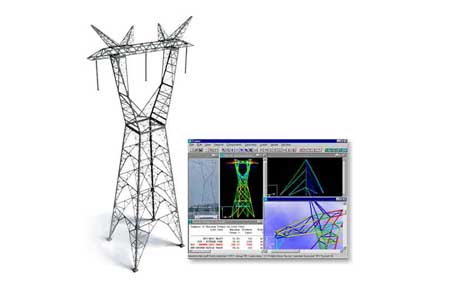

The design and engineering unit is the first and key step in all projects, which by having expert staff and software and hardware facilities to design structures and connections according to relevant standards such as ASCE, IEEE and other parameters for the design of power transmission towers (without voltage restrictions) and the number of circuits) and telecommunications, and the structure of electric substations and other metal structures, compared to the preparation of linear and then workshop plans. This unit is proud of the successful design and type test of 50 types of power transmission towers in the reliable tower testing stations of Iran and around the world.

You can find the list of towers built in Yasan company from Download here do it.

Type test

One of the requirements of new transmission line towers is to perform the type test process. This station belongs to Niro Research Institute located in Arak, a short distance from Yasan company's factory address, which has increased the speed and quality of type test services. This station is the largest tower testing station in the Middle East, which is the most reliable tower testing station in Iran with the IEC60652-2002 standard.

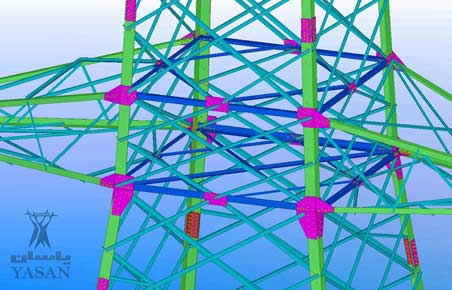

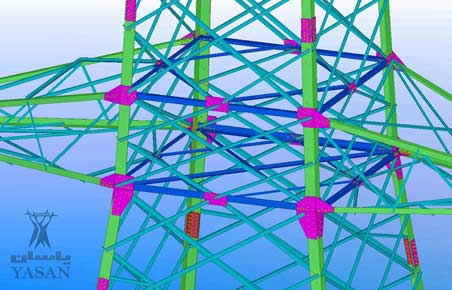

Designing

The product of this unit is the knowledge and practice of the metal structures industry. Therefore, by investing in this unit, this company has created a unique software called Yas Tower to perform the linear design of the tower and the virtual type test of the tower. This software has been patented by Yasan company in 2010, which has led to significant savings for testing new tower samples. It is generally used together with other software such as Autocad, TEKLA and Bocad to design the connections of power transmission towers.

Production

Production of metal structures is one of the main service sectors of Yasan company. All types of metal structures are produced according to the provided drawings according to DIN standards. All processes of drilling, marking, cutting, bending in this department are performed by fully automatic CNC and semi-automatic machines

Structure production

The structural production units of the company include CNC workshop, Plate workshop and structure workshop. CNC workshop is an example of fully automatic production of this company. The structures are produced from the plan to the final product without human intervention by precise Italian machines. Material technology is also one of the activities of the planning unit, which creates the least amount of loss in the production process by checking the dimensions of the parts. This reduces the cost and increases the production speed.

Galvanization

This company has started providing services to various sectors of the industry since 2001 and has been recognized as one of the prominent companies in the domestic and foreign arenas by providing quality products and services at competitive prices. The galvanizing process is done by dipping (hot-dip galvanizing) by immersing steel parts in a molten zinc bath according to the ASTM A123 standard. Due to the fact that the steel parts are completely immersed in molten zinc in this method, their outer surface is completely covered and is protected from the effects of corrosion caused by atmospheric factors and water. In this company, the galvanization process is performed on a wide range of products as follows: Mesh towers, telecommunication towers, telescopic towers, industrial grating, pipes, corners, cans, guard rail and....

For more information, you can check the galvanized catalog of Yasan company from Download here do it.

Packaging and shipping

The manufactured product is sorted and organized in the product warehouse according to the order group and type. Also, this company packs products in different ways according to the customer's request. Sorting of products before packaging is done by experienced personnel in a space of more than 2000 square meters with sorting equipment before sending to the site according to customers' request. All stages of sorting, packing and storage are carefully inspected by the quality control team to ensure the health and quality of the parts. The transportation of all parts according to the necessary standards is carried out in both open and container forms and according to the agreed Incoterms, they are delivered to the customers.

MANUFACTURE

At this stage production department begins its activities according to supplied materials and engineering outputs. At first step Planning and Programming department analyses priorities and calculates optimum procedures to reduce as much leftover as possible. Thereafter, certified workshop drawings are issued by planning and programming department for production line.

QUALITY CONTROL

Production line includes three phases: Fabrication, Galvanization, and Packing which is operating under supervision of quality control team.

DESGIN

Engineering department starts assessing drawings and technical documents to ensure about optimum design for given loadings. They are also able to design towers according to weather condition of target location and line specifications in case there is no drawings and loadings. After acceptance of clients, the project goes to production section via engineering outputs including BOM and drawings.

PACKING FINISHED PRODUCT

Packing finished product is important to preserve parts from erosion and possible damages. At this stage quality control has checked all aspects of parts’ quality to be in compliance with applied standards. After packing all bundles and boxes are checked with QC team again to ensure about right packing.

CNC PLATE

Three fully equipped workshops are responsible for fabrication including CNC workshop, Plate Workshop and Structure workshop. All workshops are responsible for process of cutting, punching, bending, and marking.

GALVANIZATION

Galvanization services have been started since 2002. YASAN has gained credibility as one of the leading companies in domestic and foreign markets by providing quality galvanizing services at competitive prices. Immersion galvanizing process (hot galvanizing) is done by immersing steel parts in molten zinc according to ASTM A123 standard. In this company, the galvanizing process is performed on a variety of products as follows: Lattice Towers, Telecommunication Towers, Monopole Towers, Industrial Grating, Pipes, Guard Rails, etc.

For more information, you can download the Galvanized Catalogue of Yasan company here.